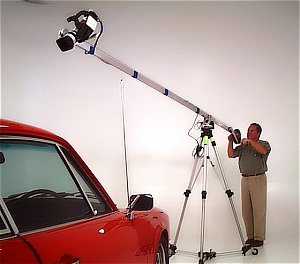

Drawing heavily on extensive experience in the Hollywood film industry and his engineering background, Bob Jones, of Costa Mesa, California has produced a very smooth, easy-to-use camera boom that's not only affordable but tough enough to support larger DV camcorders such as the Sony DSR-200. Dubbed the SkyCrane and available in several configurations, Jones has found that the popularity of his invention is spreading as increasing numbers of shooters are discovering it through the internet and trade shows.

Constructed of aircraft-quality aluminum box tubing, the SkyCrane is really two booms in one. The primary component, which is the control end of the boom including the counterweights, operating handles and tripod mount, can function on its own as a short jib arm a couple feet in length. However, with the supplied extensions, the SkyCrane also becomes a full-grown camera boom, easily hitting altitudes of twelve feet or more depending on tripod height (any higher and you'll need a pilot's license). The standard extension is three feet long, making the entire boom length from the tripod mount about five feet in length. Jones also offers optional four and five foot extensions, giving the SkyCrane some serious "reach."

The SkyCrane requires a fairly substantial tripod, and Jones recommends the Bogen 3061 or heavier. The control end of the boom mounts directly to the tripod itself and rotates very smoothly in both vertical and horizontal axes on precision sealed ball bearings. The camera mounting bracket also rotates through the vertical axis, and is controlled by a drive cable over a set of pulleys and a handle at the operating end. The camera head can spin 360 degrees and the amount of initial camera head tilt is easily adjustable. Drive cables are included for both the short jib arm and the longer extension, and the camera mounting bracket can be removed and remounted in minutes with a crescent wrench.

The SkyCrane requires a fairly substantial tripod, and Jones recommends the Bogen 3061 or heavier. The control end of the boom mounts directly to the tripod itself and rotates very smoothly in both vertical and horizontal axes on precision sealed ball bearings. The camera mounting bracket also rotates through the vertical axis, and is controlled by a drive cable over a set of pulleys and a handle at the operating end. The camera head can spin 360 degrees and the amount of initial camera head tilt is easily adjustable. Drive cables are included for both the short jib arm and the longer extension, and the camera mounting bracket can be removed and remounted in minutes with a crescent wrench.

The amount of counterweights that must be hung on the control end to balance the entire boom assembly depends on the weight of the camera and the length of the boom extension. The counterweight mount is on a sliding arm at the back of the control end, allowing finely tuned weight adjustments. A distinct advantage of this arrangement is the ability to barely trim out the counterweight just slightly, so that you can start a shot high and let gravity do the work for you… resulting in a slow, smooth, sweeping camera move. To save shipping expenses and unnecessary costs to the user, Jones suggests using readily available weightlifting discs for SkyCrane counterweights.

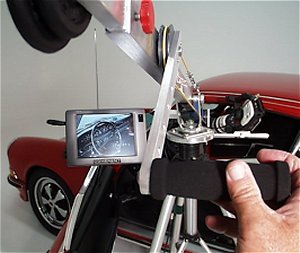

Among a number of other SkyCrane accessories, a bracket which can support an LCD monitor mounts to the tripod head itself, staying in a comfortable, fixed viewing position while the boom itself is in motion. Once you've had fun flying a camcorder on the SkyCrane and inventing new angles to shoot from, you'll be looking for excuses to use it whenever you can.

Among a number of other SkyCrane accessories, a bracket which can support an LCD monitor mounts to the tripod head itself, staying in a comfortable, fixed viewing position while the boom itself is in motion. Once you've had fun flying a camcorder on the SkyCrane and inventing new angles to shoot from, you'll be looking for excuses to use it whenever you can.

SkyCrane inventor Bob jones notes: I have worked in the film industry on and off for the past eighteen years, from working on sound stages to field locations in as many states as you can name. All of my film experience has been with the automotive industry, basically making sure that the product is correct, and is set up properly for camera angle. I have had the pleasure of working with some of the industry's most talented people from Directors to Grips and everyone in between. I have worked with and under such directors as Joe Pitka, Doug Taub and Steve Horn and not to mention some of the most heavy hitting advertising agencies in the business such as B.B.D.O and Bozell World Wide, just to name a few.

A close friend of mine, David Howard, joined me just recently to form a small video production company. Over the course of several months we have amassed a rather impressive amount of state of the art digital video gear, from the Canon XL1, Sony VX-1000, Mac NLE platform using Radius, SteadyCam Jr., wireless mics, etc. We thought we had it all but not quite (the money)! Well, you know the rest. You never stop spending in this business.

In one of our first major projects, we wanted to shoot some creative high angle shots and found ourselves trying to accomplish this without the proper piece of equipment. So we took on the task of finding a camera boom (also called a jib or a jib-arm) in order to achieve the look we were after. There were several booms to choose from, ranging in price from $400 to $2,000. Unfortunately we choose the least expensive, and it turned out to be a big mistake. The boom we purchased (for a rather modest sum,) seemed a bit flimsy... but, for the price and what our pocketbooks would allow (and after all of our previous spending), we figured we'd give it a go. To our dismay, that boom was quite inadequate in terms of offering stability and support to the heavier of our cameras, the Canon XL1. Another of major concern of ours was the risk of damage to our XL1 or to our expensive fluid head. The boom we bought would have been adequate for smaller (lighter weight) cameras... however, we needed something more versatile and we needed to remedy this problem without additional major spending.

In one of our first major projects, we wanted to shoot some creative high angle shots and found ourselves trying to accomplish this without the proper piece of equipment. So we took on the task of finding a camera boom (also called a jib or a jib-arm) in order to achieve the look we were after. There were several booms to choose from, ranging in price from $400 to $2,000. Unfortunately we choose the least expensive, and it turned out to be a big mistake. The boom we purchased (for a rather modest sum,) seemed a bit flimsy... but, for the price and what our pocketbooks would allow (and after all of our previous spending), we figured we'd give it a go. To our dismay, that boom was quite inadequate in terms of offering stability and support to the heavier of our cameras, the Canon XL1. Another of major concern of ours was the risk of damage to our XL1 or to our expensive fluid head. The boom we bought would have been adequate for smaller (lighter weight) cameras... however, we needed something more versatile and we needed to remedy this problem without additional major spending.

So, having the engineering background I do, David and I decided to build our own boom. My background in engineering goes back many years and involves not only "Hot Rod" and race car chassis engineering, suspension design and fabrication (back to the automotive thing), but also the design and fabrication of tools and safety products.

Those of you who follow Pro Rally, Stadium Racing and Pikes Peak winners will certainly be familiar with the name Rod Millen. I had the privilege of working for several years with Mr. Millen in his first US campaign and assisted in the design, engineering and fabrication of his first two winning Nissan (formerly Datsun) automobiles, the Datsun 510 and Mazda RX. Having been lucky enough to have had this type of background, I applied this knowledge to fabricate what we call the "SkyCrane" mini-DV camera boom.

There are some other excellent booms out there on the market that would stack up nicely against the SkyCrane, but they are more costly and certainly cannot compare in quality of material and construction. The SkyCrane is fabricated from finest materials available, individually assembled using 6061-T6 aircraft-quality aluminum heavy walled rectangular box tubing, anodized aluminum drive pulleys, precision sealed ball bearings, stainless steel carrier bolts and fasteners.

In using the heavier video cameras, camera weight is not the only issue. It's a combination of boom, camera, accessory and counter weights combined, which can add up quickly. With the counter balance being roughly three to one and a camera weighing ten pounds, you need thirty pounds of counter weight. The one real requirement here is a substantial tripod to mount the boom on,and we recommend the Bogen model 3061.

There are but a few booms that have the capabilities of the SkyCrane. Being cable driven, it has the ability to rotate the camera mount 360 degrees horizontally.

|  |

The SkyCrane incorporates its own integrated ballbearing tripod head. We also offer an optional universal LCD monitor mount, that attaches to the tripod head. This allows the boom operator full view of the monitor while panning or booming up and down. The distinct cable drive lever is multifunctional and is designed for comfort and ease of use by the operator.

The SkyCrane is truly more boom for your buck. If you're interested in having this jib for yourself, I can build one for you. Just give me a call.

The SkyCrane is truly more boom for your buck. If you're interested in having this jib for yourself, I can build one for you. Just give me a call.

Bob Jones

Picture This

Irvine, CA

(949) 631-6065